This article explores the versatility of laser marking machines and how they provide both precision and efficiency. From industrial applications to personal uses, laser marking is revolutionizing the way we do things, providing a range of options that were previously unavailable.

With its ability to etch or engrave surfaces with remarkable accuracy and in record time, it is no surprise that this technology has become so popular. In this article, we will take a closer look at how laser marking works and why it should be considered for your project needs.

We will also examine some of the common misconceptions about laser marking as well as explore some potential applications where it could be used effectively. Finally, we will discuss what kinds of materials are suitable for such processes and offer tips on getting started with your projects using laser marking machines.

Understanding Laser Marking Machines

When it comes to understanding laser marking machines, the versatility and precision they offer make them a top choice for many industries. From jewelry engraving to medical device manufacturing, these machines can reliably deliver high-quality results with extreme accuracy.

With advancements in technology, these machines are now capable of producing intricate designs and complex patterns at blazing speeds that were unimaginable before. For those considering investing in such a machine for their business operations, there are several factors worth exploring—from the type of laser used to the overall cost of operation. Laser marking is often divided into two categories: surface or material removal and ablation processes; each has unique advantages depending on your specific needs.

For example, if you’re looking for an extremely precise finish on a delicate material like glass or crystal, then the ablation process would be more ideal than a surface removal process since it can leave behind smoother edges without causing any damage to the object itself. In terms of cost considerations, it’s important to consider both capital investment costs as well as operational expenses associated with running a laser marking machine over time.

This includes factoring in maintenance costs which can vary widely depending on the make and model you choose along with any additional features you may require from your system such as safety measures or automation capabilities. Additionally, some models may offer better energy efficiency thus reducing long-term operating costs significantly compared to other options available in the market today.

Overall understanding how these machines work requires careful research but when properly maintained they provide reliable performance while offering maximum control over output quality making them an attractive option among modern businesses striving towards greater levels of efficiency in production processes while still maintaining precision craftsmanship standards throughout every step of the manufacturing cycle.

Considerations for Choosing a Laser Marking Machine

Source: optlasersgrav.com

When it comes to choosing a laser machine, several essential considerations must be taken into account. First of all, the size and power output of the laser should be carefully evaluated for the application for which the machine will be used.

The speed at which parts can be marked is also an important factor since shorter processing times often equate to higher efficiency levels across production lines. Additionally, accuracy and durability should not be overlooked; if a lower-quality material or construction is selected then malfunctions may occur more frequently resulting in costly losses due to downtime or repairs.

Furthermore, compatibility with existing systems should also take precedence when selecting a model – this ensures seamless integration with other machines onsite and helps prevent any future problems from arising due to incompatibility issues. Finally, cost should always remain top-of-mind as well; although investing in higher quality models may provide additional features that prove beneficial later on down the line, opting for a cheaper option could still meet your immediate needs while saving money upfront.

Laser Marking Machines in Car Inustry

Laser marking machines have become increasingly popular in the automotive industry due to their incredible levels of accuracy and efficiency. From customizing parts with intricate designs to serial numbers or labeling components for tracking purposes, laser marking has revolutionized how car manufacturers are able to produce quality parts quickly. Their ability to etch or engrave complex shapes without causing any damage makes them an ideal choice when it comes to tackling demanding projects that require precision and speed.

Additionally, lasers are often capable of producing markings on a variety of materials including metals, plastics, ceramics and rubber—allowing for maximum versatility in production applications. Laser marking is also incredibly cost-effective since there is no need for harsh chemicals nor does it generate hazardous waste thus eliminating potential environmental risks associated with other methods like chemical etching.

As technology continues to advance in this field, more companies will begin using laser marking machines as they offer unparalleled levels of accuracy while maintaining efficiency throughout the entire production cycle.

Conclusion

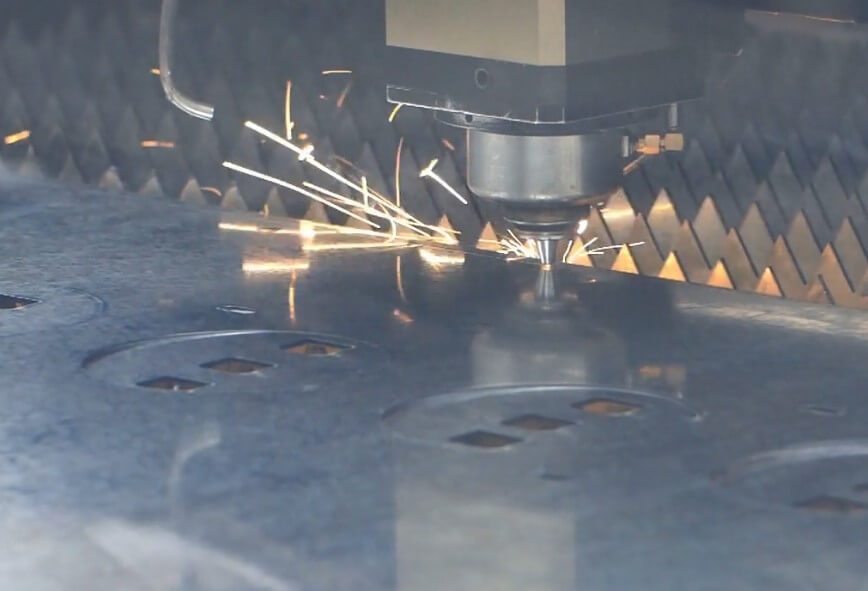

Source: www.metalworkmasters.com

Laser Marking Machines are an invaluable asset in industrial production, offering a level of precision and efficiency that is unmatched. Their versatile nature allows them to be used for a variety of purposes, from cutting through hard materials to engraving delicate designs on surfaces.

With their ability to process complex tasks quickly and accurately, Laser Marking Machines provide businesses with the capability to reduce costs while increasing productivity. This makes them an essential tool for any business looking to harness the power of precision and efficiency.