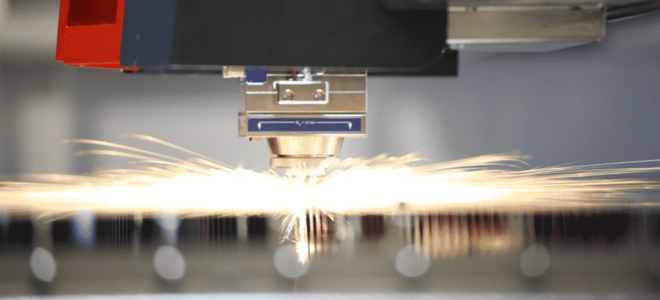

Are you looking for the ultimate guide to sheet and tube fiber laser cutting machines? Whether it’s for precision or versatility, this guide will help you get the most out of your machine. Here will take a look at the advantages and disadvantages of these powerful tools, as well as how to maximize their capabilities.

Well also discuss some tips and tricks on getting started with sheet and tube lasers so that you can make sure your project is successful. So if youre ready to find out more about maximizing your precision and versatility with fiber laser cutting machines, then read on!

Understanding the Benefits of Using a Fiber Laser Cutter

When it comes to laser-cutting machines, fiber lasers provide unparalleled precision and versatility. Understanding the various benefits of using this type of machine can help you make an informed decision when choosing a sheet and tube fiber laser cutter for your business.

One major benefit is that fiber lasers are capable of producing complex shapes with incredible accuracy. This helps reduce production time while ensuring that the finished pieces are exactly what was intended.

Additionally, the cutting process creates minimal waste as compared to other methods like plasma or waterjet cutters. Fiber laser cutters also offer greater flexibility than other types of machines due to their higher power outputs and ability to adjust settings such as speed, pulse width, and focus spot size based on material thickness.

This makes them ideal for working with thin materials without risking damage from heat or distortion from the excessive force being applied during the cutting process. Furthermore, because they require less energy than traditional CO2 models they are much more cost-effective in terms of operating expenses over time. Finally, these machines have a longer life span due to their lack of wearing parts which mean less downtime for maintenance issues or repairs resulting in increased productivity overall.

The combination of all these advantages makes investing in a sheet and tube fiber laser cutter a wise choice for any business looking to maximize its efficiency while maintaining high levels of quality control over its products at an affordable price point

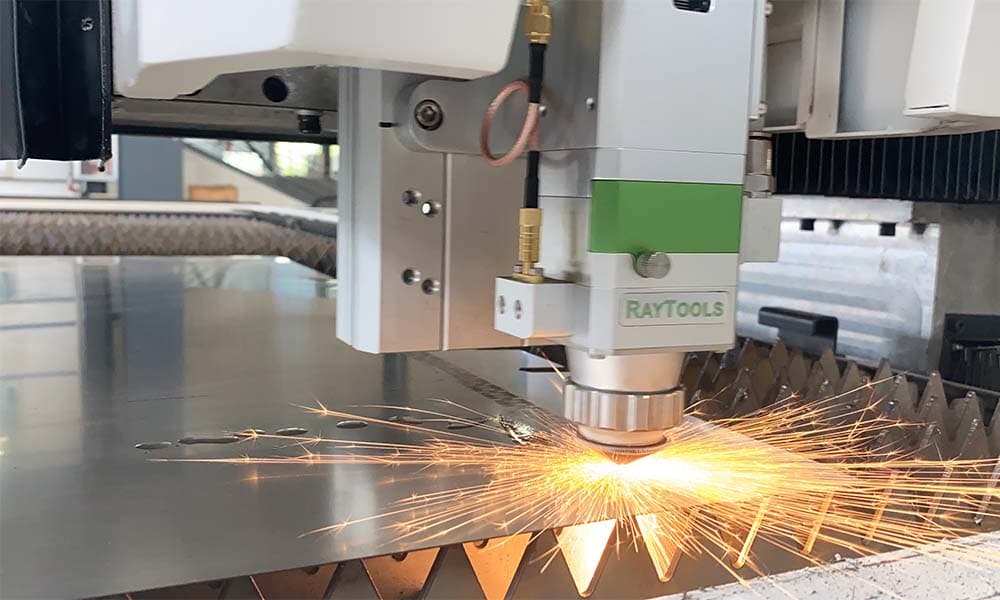

Choosing the Right Type of Fiber Laser Machine for Your Needs

Source: akscutting.com

When selecting a fiber laser machine for your needs, it is important to consider the precision and versatility of the system. For sheet metal applications, you need a cutting machine capable of producing intricate designs that can be operated with high levels of accuracy.

Tube laser machines are ideal when you require complex geometries or precise cuts in round and square tubes. The right type of fiber laser cutting machine should provide an efficient process while ensuring the highest quality results.

It is also essential to evaluate the speed and power requirements for your application. High-powered systems are specifically designed to cut thicker materials more quickly than low-powered models, reducing production times significantly.

Additionally, some machines have adjustable settings so they can be optimized for different materials and thicknesses without compromising accuracy or precision. Another factor to consider when choosing the most suitable fiber laser machine for your needs is its ability to integrate into existing manufacturing processes or automation lines seamlessly.

This will help ensure smooth operations within those production environments while eliminating any downtime caused by manual setup steps or equipment malfunctions. Lastly, look at other features such as maintenance requirements, safety protocols, cost savings over time (due to energy efficiency), etc.

, which may influence your decision when selecting a specific model from a range of options available on the market today

Ensuring Maximum Precision and Versatility in Your Cuts

When it comes to achieving maximum precision and versatility with sheet and tube fiber laser cutting machines, there are a variety of factors that need to be taken into account. For starters, the machine should have advanced technology that allows for accurate cutting at various levels.

Additionally, the machine should be able to process materials of different thicknesses without compromising accuracy or quality. As such, users must ensure that they select a high-quality product with features designed specifically for their needs. Beyond simply selecting an appropriate machine, operators must consider other variables when aiming for optimal precision and versatility in their cuts.

This includes making sure the material being cut is properly aligned before beginning as well as ensuring that any necessary adjustments to settings like speed or power are made accordingly throughout each job run. In addition, proper maintenance of the tooling involved will also help maximize results while minimizing downtime due to potential wear-and-tear issues over time.

Ultimately, regardless of which specific model is chosen or how experienced a user may be operating it; understanding all aspects associated with sheet and tube fiber laser cutting machines will ultimately determine how successful one can truly become when striving for maximum precision and versatility in every cut produced by these powerful tools!

Maintenance Considerations for Optimal Performance and Efficiency

Source: www.thefabricator.com

When operating sheet and tube fiber laser cutting machines, several considerations must be taken into account to ensure the utmost precision and versatility. The most important factor is regular maintenance of your machine; failure to properly maintain these complex machines can lead to decreased efficiency, subpar performance, or even serious damage.

Regular checkups should include examining the lens head mirror alignment as well as any other moving parts like guide rails or sliders. Additionally, it is important to keep an eye on various components such as gas lines, pump systems, capacitors, and water temperature control devices which require frequent calibration to remain accurate.

Finally, all electrical elements should be inspected regularly for any signs of wear or corrosion – this will prevent issues from arising due to incorrect voltage levels or overcurrents in your system. By taking proper care of your machine with regular maintenance checks you can guarantee optimal performance and efficient operation at all times!

Maximizing Precision and Versatility in the Car Industry

The car industry is constantly evolving, with manufacturers seeking cutting-edge technologies that can deliver both precision and versatility. Among the revolutionary advancements in the field, sheet and tube fiber laser cutting machines have emerged as game-changers, offering unparalleled capabilities in the fabrication of car components. By harnessing the power of laser technology, these machines provide automotive manufacturers with the means to achieve exceptional precision and unmatched versatility, taking the production of cars to new heights.

At the core of sheet and tube fiber laser cutting machines lies the ability to precisely and efficiently cut a wide range of materials, including metals like steel, aluminum, and even advanced alloys. The laser beam emitted by these machines is carefully controlled to achieve a level of accuracy that was once unimaginable. From intricate sheet metal parts to complex tube structures, the laser cutting process ensures that every cut is executed with exceptional precision, resulting in components that fit seamlessly together during assembly.

The versatility of sheet and tube fiber laser cutting machines is a key attribute that sets them apart in the car industry. These machines can handle various types of materials, thicknesses, and geometries, allowing manufacturers to create a diverse range of car components. Whether it’s body panels, chassis parts, exhaust systems, or intricate tube structures, laser cutting machines offer the flexibility to tackle a wide array of production needs. This versatility enables automakers to optimize their manufacturing processes, streamline production lines, and respond effectively to the evolving demands of the market.

One of the significant advantages of fiber laser cutting technology is its ability to work with both flat sheets and tubular structures. This versatility eliminates the need for multiple cutting methods, saving time, and reducing costs. With sheet and tube fiber laser cutting machines, manufacturers can seamlessly transition from cutting sheet metal to processing tubes, ensuring a smooth and efficient production workflow. This integrated approach enhances overall productivity, eliminates potential errors caused by switching between different machines, and accelerates time-to-market for new car models.

The precision and versatility offered by sheet and tube fiber laser cutting machines not only improve the manufacturing process but also contribute to the overall quality and performance of cars. The precise cuts achieved through laser technology ensure accurate fitment of components, reducing the need for adjustments during assembly. This leads to improved structural integrity, enhanced safety, and a refined driving experience for car owners. Furthermore, the versatility of laser-cutting machines allows manufacturers to explore innovative designs, lightweight materials, and complex geometries, resulting in vehicles that are both visually appealing and technologically advanced.

Beyond their technical capabilities, sheet and tube fiber laser cutting machines also align with the growing emphasis on sustainability in the car industry. By enabling precise and efficient material usage, these machines minimize waste and optimize resource utilization. With the ability to process a variety of materials, including lightweight alloys, manufacturers can design cars that are more fuel-efficient and environmentally friendly. The reduced material waste and energy consumption associated with laser cutting technology contribute to a greener automotive sector and support the industry’s commitment to sustainability.

As the car industry continues to evolve, sheet and tube fiber laser cutting machines are poised to play a vital role in driving innovation and setting new benchmarks for precision and versatility. Ongoing advancements in laser technology promise even greater speed, accuracy, and adaptability, enabling manufacturers to push the boundaries of design and engineering. With the ability to customize cutting parameters and optimize production processes, laser cutting machines empower automotive manufacturers to deliver vehicles that meet the diverse needs and preferences of car enthusiasts worldwide.

Conclusion

Source: www.laser-cutting-ipg.com

The Laser Cutting Machines are a great way to maximize precision and versatility when it comes to sheet and tube fabrication. They offer an efficient, cost-effective solution that can be used in many different industries ranging from automotive manufacturing to medical device production.

With the ability to cut complex shapes with accuracy and speed, these machines provide an unparalleled level of cutting power for both thin and thick metal sheets. The Ultimate Guide to Sheet and Tube Fiber Laser Cutting Machines provides valuable information on how you can make the most out of this technology for your business needs.