The automotive industry is constantly evolving with advances in technology that drive innovation and revolutionize the way cars are manufactured. Laser-cutting machines have brought a new level of precision to car production, allowing for faster, more accurate, and more efficient workflows than ever before.

With this new technology, manufacturers can produce higher-quality parts with greater speed and accuracy than ever before. This article will explore how laser-cutting machines are driving innovation in the automotive industry by providing an in-depth look at their capabilities, advantages over traditional methods of manufacturing, and their potential for future applications.

The Impact of Laser Cutting Machines on Automotive Industry Innovation

Laser-cutting machines have revolutionized the automotive industry by ushering in a new era of precision and innovation.

Laser-cutting machines have revolutionized the automotive industry by ushering in a new era of precision and innovation.

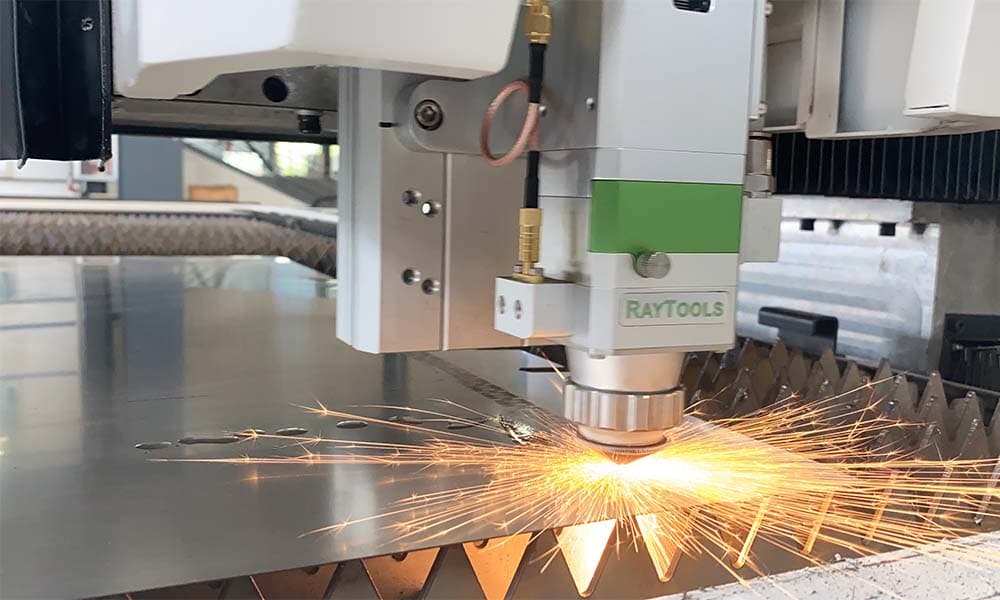

These powerful tools are capable of achieving precise measurements with unparalleled accuracy, allowing manufacturers to create complex designs that were once thought impossible. What’s more, laser cutting machines can be used on a variety of materials including metal alloys and plastics, making them an incredibly versatile option for automotive designers.

The impact that these tools have had on the industry is undeniable; they’ve allowed automakers to quickly produce high-quality products while reducing manufacturing costs at the same time. The introduction of laser-cutting machines has changed how cars are designed and manufactured.

Automakers now have access to sophisticated software programs that allow them to design intricate parts with ease, creating innovative components with enhanced performance capabilities. Additionally, these programs generate detailed instructions for their highly accurate equipment so even novice operators can achieve excellent results every time.

This newfound capability has enabled automakers to develop more efficient production processes which ultimately leads to faster delivery times and cost savings passed along directly to consumers. Not only do laser cutting machines provide improved efficiency but they also offer increased safety measures as well since there is no need for manual handling or welding during assembly operations anymore – two common areas where accidents occur frequently in traditional auto manufacturing plants.

In addition, modern lasers use advanced cooling technology which eliminates sparks caused by friction thus preventing any potential fires from occurring within the facility itself – a bonus when it comes to workplace safety standards! Overall, it’s clear that laser cutting machines have had a major positive influence on automotive innovation across many different facets: from enhanced precision levels leading to higher quality final products; reduced labor costs through automation; improved safety features due to less manual work being done; right down to quicker turnaround times thanks its ability process large volumes quickly and accurately without compromising accuracy or end product integrity whatsoever! It’s this combination of benefits which makes it such an invaluable tool – one surefire way automotive companies can stay ahead in today’s ever-evolving marketplace!

Benefits of Implementing Laser Cutting Technology in the Auto Manufacturing Process

Source: otegotextile.com

The implementation of laser cutting technology in the auto manufacturing process offers numerous advantages. For starters, it drives innovation by allowing for faster and more accurate production times as well as improved precision during fabrication processes.

Laser-cutting machines can cut through metal with a high degree of accuracy and speed, eliminating wasted materials or inaccurate cuts that can occur when using traditional methods. This technology also allows manufacturers to create complex designs with intricate details that were once impossible to achieve through other means of fabrication.

Additionally, laser-cut parts are free from burrs and other imperfections which improves product quality immensely and reduces costs associated with post-processing operations such as machining or grinding. Furthermore, this advanced method results in minimal material waste since it does not require costly punching tools nor does it demand large setup times like conventional die-cutting processes do.

In conclusion, implementing laser cutting technology in the automotive industry provides several benefits including increased productivity and accuracy along with reduced costs due to minimized material wastage – all factors essential for driving innovation within the sector today!

Achieving Increased Precision with Laser Cutting Machines for Car Parts Production

Source: www.thefabricator.com

The automotive industry is rapidly innovating through the use of laser-cutting machines to achieve increased precision in car parts production. Laser-cutting technology offers a range of advantages over traditional methods, including improved accuracy and speed as well as greater flexibility when it comes to complex shapes and profiles.

With laser cutters able to work on even the most intricate designs with high levels of detail, auto manufacturers can create components that are more accurate than ever before. Not only does this allow for better-quality car parts but also enhances safety and reliability across all vehicles produced.

In addition, using laser cutters helps reduce costs associated with producing components while also speeding up the entire production process. With such advanced capabilities, it’s no wonder why many automotive companies have been turning to laser-cutting machines to stay ahead of their competitors.

For example, one company has seen an increase in productivity by 40% since introducing lasers into their manufacturing process!

This is just one example of how these powerful tools are revolutionizing car part production – providing faster turnaround times at lower costs while still maintaining quality standards set by the industry’s leading brands. Overall, laser cutting ensures increased precision for parts that require tight tolerances – making them perfect for any application where accuracy matters most.

Conclusion

Source: www.laser-cutting-ipg.com

The automotive industry is continuously looking for ways to innovate to keep up with the changing demands and needs of its customers. Laser cutting machines, such as Thunder Lasers cutters, are becoming increasingly popular due to their accuracy and ability to create intricate designs quickly.

The precision that laser cutters offer allows companies in the automotive industry to produce quick and precise results while keeping costs low. This technology has allowed automakers across the globe to design components more efficiently, leading them one step closer to revolutionizing the way they produce cars and other vehicles.